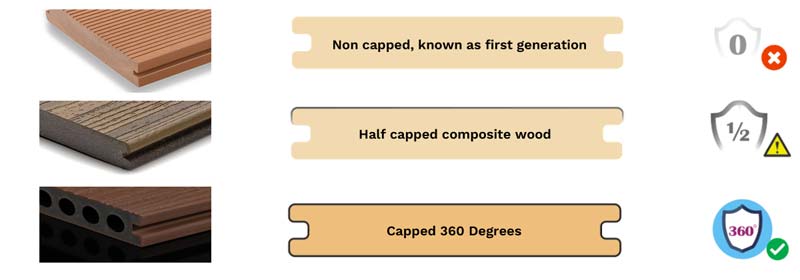

Over the past 30 years, the WPC industry continues to move forward, thanks in part to the increased demand for outdoor living space, the need for sustainable decking materials will continue to grow. WPC materials that can withstand harsh climate conditions, low maintenance, and look great without harming the environment are likely to become essential for the decks of the future. There are various WPC composite products on the market with the technology development. From the aspect of covering layer coverage, we can see that PE plastic wood is divided into four types:

1. 360-degree all-round coating layer

2. The slot position of the decking is cut, and the coating layer is not completely coated

3. The coating layer can only cover the upper half of the decking

4. The uncapped composite decking/ 1st generation decking

The first three kinds of wpc have an outer layer, which belongs to co-extrusion wpc also named 2nd generation. The fourth one is the most classic composite decking, we call it the first generation. From the application of these four kinds of wpc, we can see the future development direction of composite WPC decking.

The uncapped, first-generation composite decking:

In the first generation of plastic wood, the surface layer containing wood powder is directly exposed to harsh environmental in different climates. Compared with co-extrusion products, it is vulnerable to the erosion of strong UV, mold, stain. In the past few years of actual installation, we have seen similar problems. If you’re more in the mood for something traditional, then first-generation will be an economic option. But if your budget is well and want to choose a decking with long service life, co-extrusion decking will be your best choice and you get the extra benefits of a co-extrusion decking.

The decking with incompleted coating layer:

The co-extrusion decking without complete coating, only parts of the plastic wood are covered by a coating layer, solves some of the problems mentioned above. However, due to the incompleted coating, there’s no coating layer on the bottom, the decking will easy to absorb water which will lead the expansion and bending deformation problems, and the serious even the slot position is pulled to crack.

360-degree fully capped co-extrusion decking:

The 360-degree complete coating layer could provide full protection for the core, which can resist the effects of harsh environments, moisture, strong UV, mold and prevent decking from cracking and deformation. We all know that the composition of the core material is wood powder, PE plastics and additives, and the coating layer is made of advanced HPE and special additives, which makes the decking has a very low water absorption rate to effectively prevent water from entering the core. Everyone who had use the fully capped co-extrusion decking will be surprised by its excellent performance, such as rot resistance, no cracking, no fading. Besides, high-density polyethylene coating of the capped decking is more resistant to stains and scratches and no need to brush, paint or seal, basically no maintenance, save your money and time.

Wallong dedicates to providing fully capped co-extrusion decking to our customers, and we believe that co-extrusion products will be widely used and recognised by all consumers in the near future. Talk to our sales for more details: inquiry@wallongwpc.com